Routing

Feel the power of possessing the entire picture of your business process and needs set to their time frames; learn what to do, discover the intricacies of your trade, and master the complexities of the procedures.

Severity: 8192

Message: Creation of dynamic property CI_URI::$config is deprecated

Filename: core/URI.php

Line Number: 101

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Router::$uri is deprecated

Filename: core/Router.php

Line Number: 127

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property Planning::$benchmark is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property Planning::$hooks is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property Planning::$config is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property Planning::$log is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property Planning::$utf8 is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property Planning::$uri is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property Planning::$exceptions is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property Planning::$router is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property Planning::$output is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property Planning::$security is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property Planning::$input is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property Planning::$lang is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property Planning::$load is deprecated

Filename: core/Controller.php

Line Number: 78

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Loader::$benchmark is deprecated

Filename: core/Loader.php

Line Number: 925

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\application\controllers\planning.php

Line: 15

Function: view

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Loader::$hooks is deprecated

Filename: core/Loader.php

Line Number: 925

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\application\controllers\planning.php

Line: 15

Function: view

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Loader::$config is deprecated

Filename: core/Loader.php

Line Number: 925

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\application\controllers\planning.php

Line: 15

Function: view

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Loader::$log is deprecated

Filename: core/Loader.php

Line Number: 925

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\application\controllers\planning.php

Line: 15

Function: view

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Loader::$utf8 is deprecated

Filename: core/Loader.php

Line Number: 925

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\application\controllers\planning.php

Line: 15

Function: view

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Loader::$uri is deprecated

Filename: core/Loader.php

Line Number: 925

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\application\controllers\planning.php

Line: 15

Function: view

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Loader::$exceptions is deprecated

Filename: core/Loader.php

Line Number: 925

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\application\controllers\planning.php

Line: 15

Function: view

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Loader::$router is deprecated

Filename: core/Loader.php

Line Number: 925

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\application\controllers\planning.php

Line: 15

Function: view

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Loader::$output is deprecated

Filename: core/Loader.php

Line Number: 925

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\application\controllers\planning.php

Line: 15

Function: view

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Loader::$security is deprecated

Filename: core/Loader.php

Line Number: 925

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\application\controllers\planning.php

Line: 15

Function: view

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Loader::$input is deprecated

Filename: core/Loader.php

Line Number: 925

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\application\controllers\planning.php

Line: 15

Function: view

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Loader::$lang is deprecated

Filename: core/Loader.php

Line Number: 925

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\application\controllers\planning.php

Line: 15

Function: view

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Severity: 8192

Message: Creation of dynamic property CI_Loader::$load is deprecated

Filename: core/Loader.php

Line Number: 925

Backtrace:

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\application\controllers\planning.php

Line: 15

Function: view

File: D:\INETPUB\VHOSTS\roadmapit.com\demo.roadmapit.com\roadmap\index.php

Line: 315

Function: require_once

Smart prioritization of production based on critical ratio rule, earliest due date, and slack time remaining rule provides optimum customer satisfaction.

MRP II's RCCP and CRP run on thoroughly analyzed real-time data, furnishes clear cut solution to your actual resources Vs required resources queries.

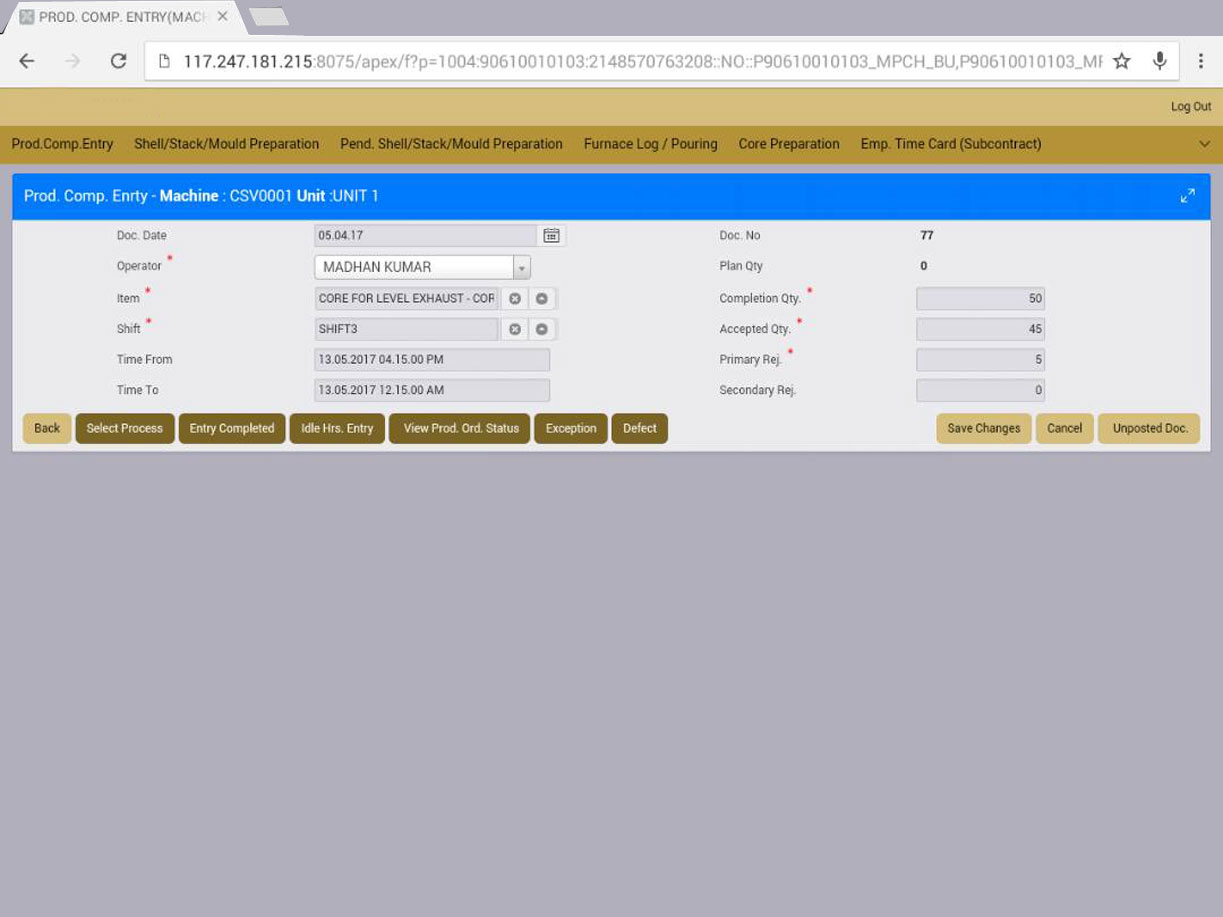

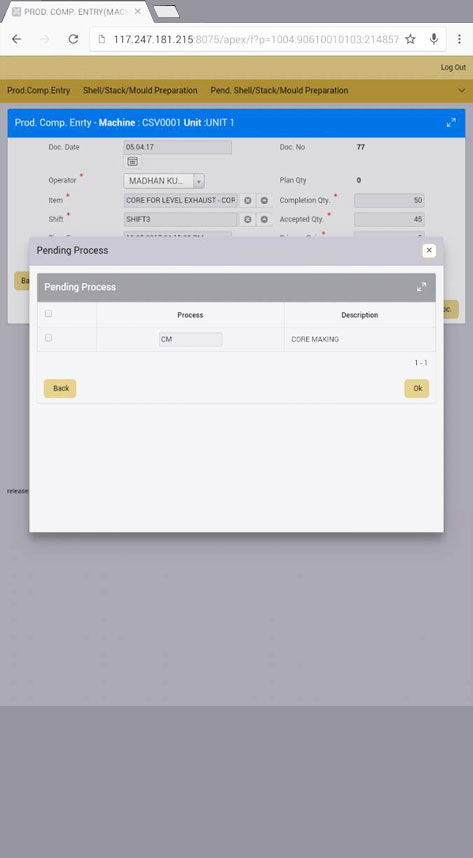

Entire Work in Progress at shop floor is presented on a single screen with representation of work done/ not done status through binary number (0 and 1)

Feel the power of possessing the entire picture of your business process and needs set to their time frames; learn what to do, discover the intricacies of your trade, and master the complexities of the procedures.

Appraise your stock, gear, and money, against the factors to fix the produce; concoct fool-proof planning and workflow linking; achieve efficient fabrication; and deliver produce uncompromised by time and quality.

Read MoreBe forecasted with the Do's and Dont's of your Production process, projected through an analysis of Inventory, workflow, and Customer demands, and meet all Production demands and never default one bit.

Read MoreEquip yourself to know when to produce, and how much to produce, while being able to wisely assign supplies, workforce and equipment for manufacturing; and confidently promise assured delivery dates.

Read MoreRein in costs via efficient Inventory control, ability to assess effects of Changes to Cost; procure and produce in accord with Demand Vs Supply reports; and aptly feed the process to ensure seamless on-time production.

Read MorePerfectly determine the resources required for your Production procedure, through RCCP and CRP tools built into the facility, and exactly negotiate the best possible adjustments to achieve best Production results.

Read MoreGet to the very center of the Production process and gain access to the entire workflow, through on-screen / visual representation of the same, and acquire full knowledge of the work in order to address all its aspects.

Read MoreCleverly allocate plant and machinery, efficiently manage manpower and processes, and prudently procure and supply to optimize Production; and prioritize wisely to deliver total customer satisfaction.

Read More

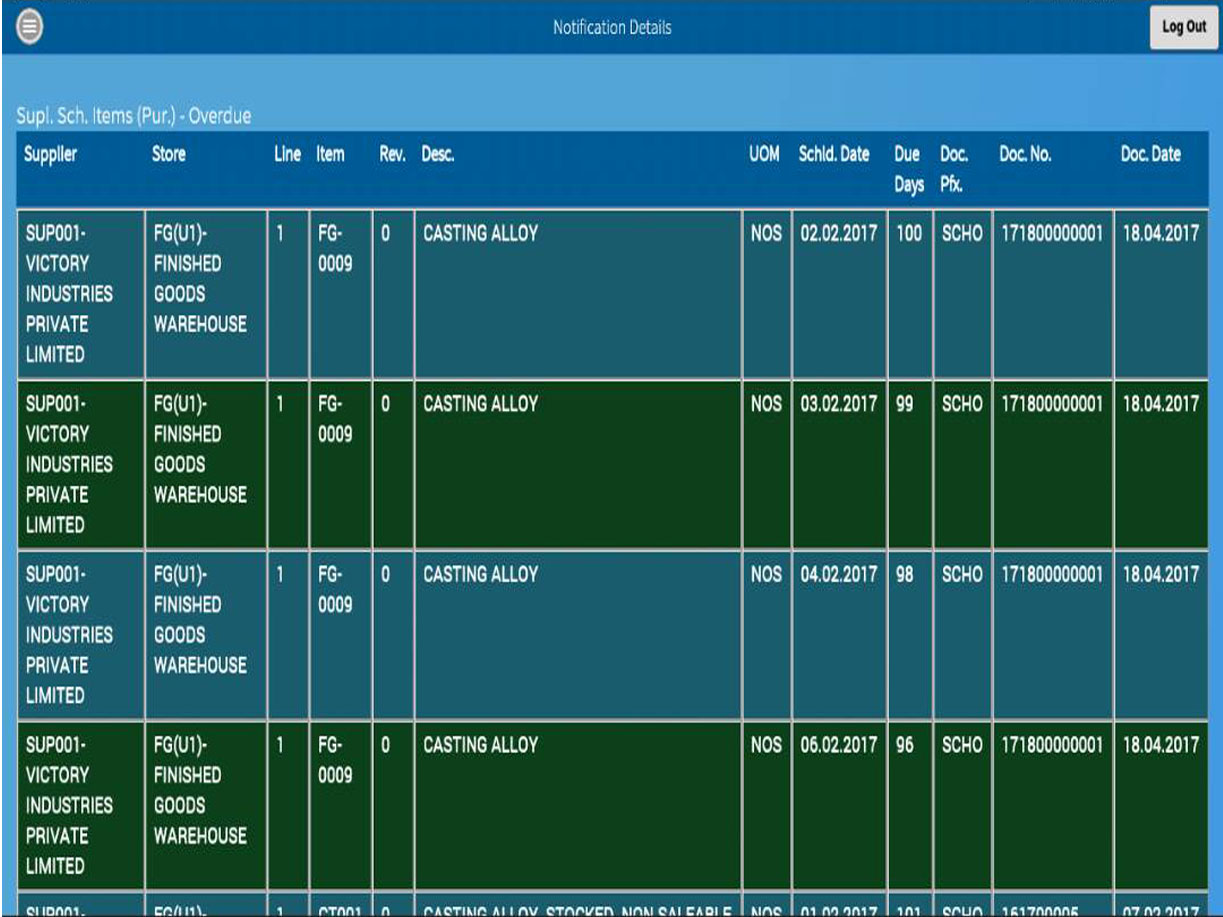

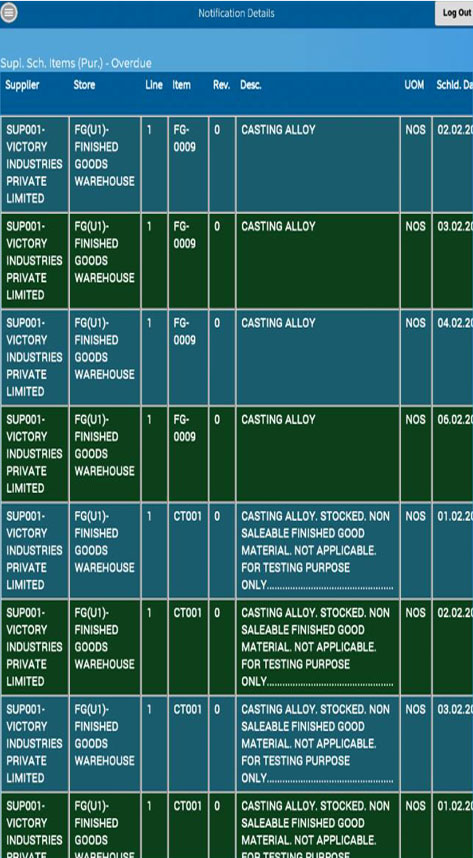

Get notifications on real-time status of Key Performance Indicators of your business through Dashboard facility, and make easy and effective decisions.

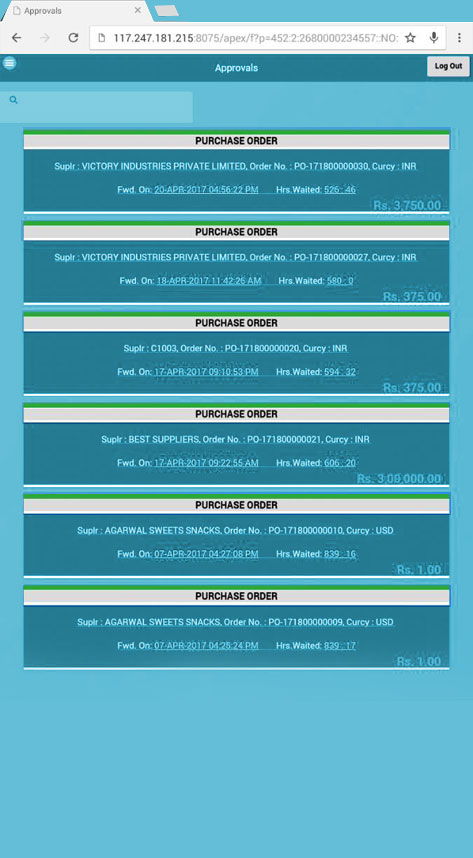

Don't be hindered by the absence of key personnel. Keep them integrated to your business from anywhere in the world through our Mobile Approval facility.

Our MRP-II enables you to make optimum use of your materials, manpower, and equipments; efficiently manage Inventory; and get the best out of your resources.

Our client is the first company in Asia to manufacture automobile service station equipments. Having sensed the huge potential and requirement in the field of servicing automobiles, our client established a R & D center to carry our Research on key products.

DownloadVAAS Group commence operations in 1980 as a trading house focusing on high quality industrial valves. Promoted by a valve technocrat, the philosophy of the group has always been to provide the user with the optimum solution to their value needs.

Download